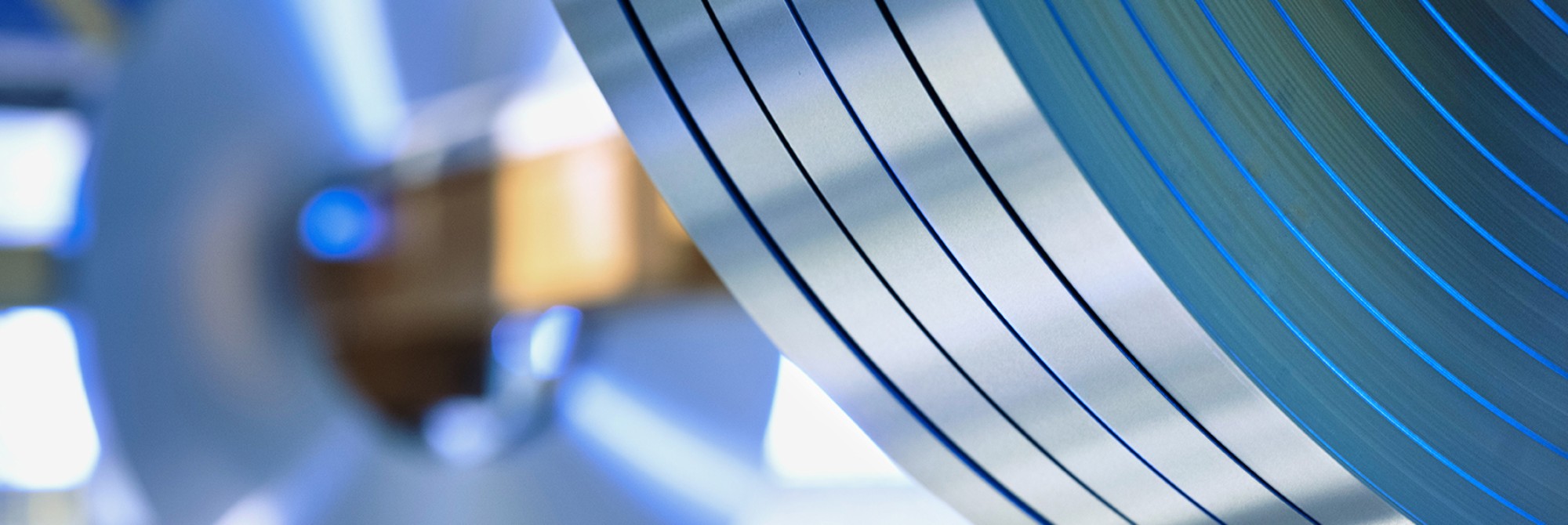

Electrical steel – The high-tech core material of the future with outstanding efficiency

The steel business of thyssenkrupp is one of the global market leader of non grain oriented high-tech electrical steels. The product range includes the semi-finished as well as the fully-finished grades. Our innovative powercore® electrical steels contribute greatly to a reduction of the remagnetization losses during the transfer and distribution of electrical energy to a minimum.